Showroom

Jib crane is a highly flexible and adaptable machine designed to fit different working conditions and industries. It is designed to enhance the output of workshops with its low-maintenance design.

Heavy-duty EOT Crane is designed with maximum capacity up to 500 tons to be used in different applications. It is used in shipbuilding, steel plant, power, nuclear, heavy/general engineering, etc.

Goliath Cranes enhance efficacy, safety and flexibility in different working conditions and industries. They can easily hold heavy loads with their capacity up to 500T.

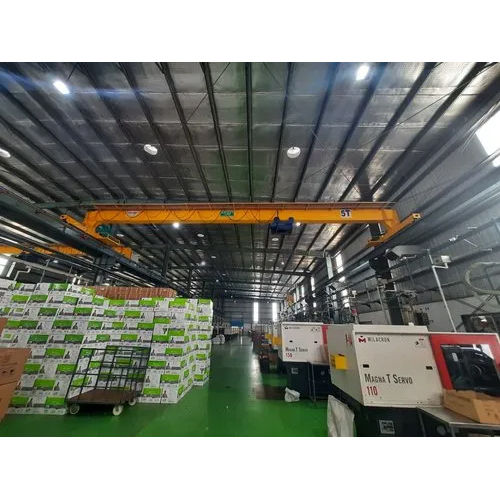

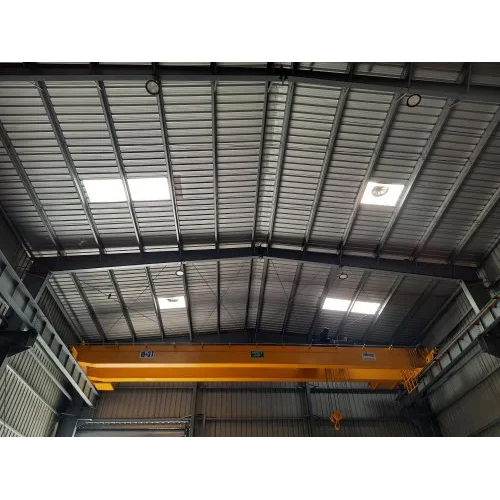

Overhead Cranes are designed with modern software and smart features to ensure to provide complete and efficient control over different material handling systems. These cranes are developed for making the lifting processes easier and efficient.

Wire Rope Hoist Cranes are used in different industrial settings to lift heavy-loads with the capacities of 80 tons. They are provided with high-tech advanced lifting features with high durability and excellent strengths.

An Overhead Traveling Crane is a lifting solution commonly used in industrial settings. It features a movable bridge that spans the workspace and efficiently lifts and transports loads, with precision. These cranes are particularly well suited for factories and warehouses as they optimize material handling, boosting productivity by moving goods within the designated area. With various configurations available to cater to requirements, they offer a reliable and efficient solution for lifting and transporting heavy loads in different industrial environments.

The Underslung EOT Crane offers versatile lifting solution designed to optimize space in industrial environments. In a Underslung EOT Crane, a runway girder is attached underneath and it efficiently lifts and moves heavy loads with precision. This type of crane is Ideal for workshops and production areas with limited headroom as they provide seamless material handling while maximizing vertical space. Their compact design and robust construction make Underslung EOT Cranes an efficient choice for industries requiring precise and space-saving lifting solutions.

Girder Cranes are provided with maximum rigidity and cost-effective design to provide the best loading and unloading results. They are provided with durable hoisting unit having high handling speeds.

These high-technology Elevators are provided in creative and high-utility designs to provide safe elevation. They are available in high-tech design with maximum safety and reliability options.

Send Inquiry

Send Inquiry  English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese